Detailed Interpretation of Corrugated Paper, a Packaging Material Every Designer Should Know

Detailed Explanation of Packaging Material – Corrugated Paper

Basic knowledge of corrugated paper

1. Commonly used types include single – corrugated paper and double – corrugated paper, which come in colors and white.

2. It is lightweight, has good structural performance and strong load – bearing capacity, and can resist moisture (commonly used in packaging such as express boxes and cartons).

3. It can achieve printing in various colors, but the printing effect is not as good as that of single – coated paper and double – coated paper. It can be combined with pasted white cardboard to achieve more vivid color printing.

4. It typically uses a case packaging machine to fold cartons formed by a robotic arm in order to fill product packaging.

The categories of corrugated paper

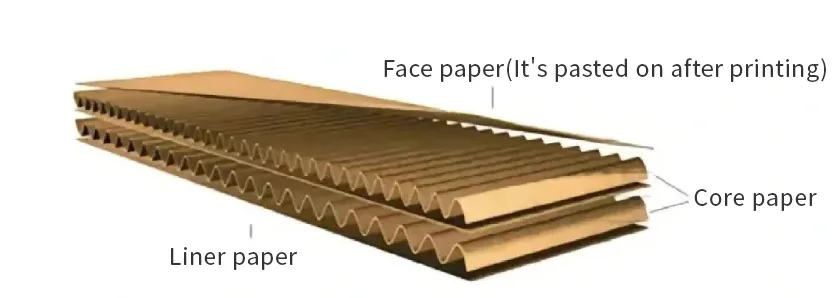

Corrugated paper generally consists of face paper, base paper, core paper, and separator paper (which will be elaborated later).

- Face paper: It is the paper pasted on the outermost layer of the corrugated paper. Materials such as white cardboard, kraft paper, double – coated paper, and grey – backed white paper can be used. Generally, its weight ranges from 125 to 310 g/m². For face paper, 250 – gram white cardboard is preferentially recommended.

- Core paper: Also known as fluting paper, it is the paper with an uneven corrugated shape in the middle. Generally, its weights are 105 – 115 g/m², 125 g/m², and 150 g/m².

- Liner paper: It is the innermost layer of the corrugated cardboard. Generally, the paper used is the same as that of the face paper.

Commonly used corrugation patterns

Commonly used corrugation patterns: A, B, C, E, F.

| Corrugation categories | Common names | Corrugation height/mm | Corrugation height/mm | Properties |

|---|---|---|---|---|

| A flute | Large corrugation | 4.5~5 | 34+2 | It has the highest compressive strength but is prone to damage. It is rich in elasticity and cushioning properties and is used for outer cartons and partition boards. |

| B flute | Small corrugation | 2.5~3 | 50+2 | It has relatively poor strength but good stability, a flat surface and can withstand high planar pressure. It is used for cartons, boxes, partition boards and liners. |

| C flute | Medium corrugation | 3.5~4 | 28+2 | The strength is between A and B. It is relatively economical in price and is widely used in China. |

| E flute | Micro corrugation | 1.1-2 | 90±2 | Thin, dense, lightweight and with good cushioning properties, it is only suitable for exquisite inner packaging and not for outer packaging cushioning materials. |

| F flute | Ultra-thin corrugation | 0.6~0.9 | 136+2 | It is used as disposable packaging for foods such as hamburgers and pastries, or as packaging for microelectronic products such as digital cameras and refrigerated goods. |

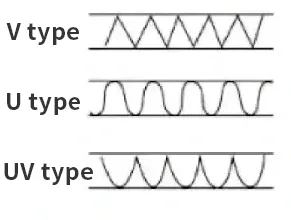

Corrugation type

Common combination methods

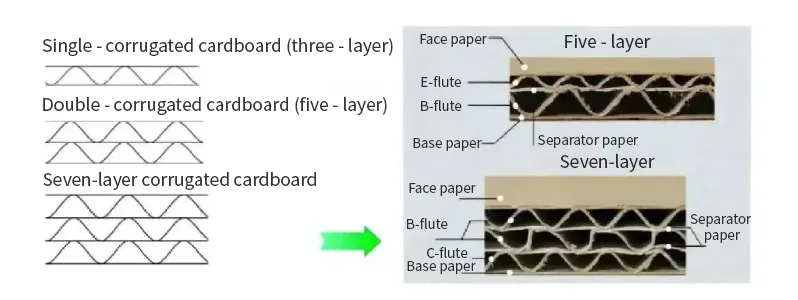

Classified by different numbers of layers, it can be divided into three – layer, five – layer and seven – layer.

The names and thicknesses of corrugations

Classified according to different numbers of layers, it can be divided into three – layer, five – layer and seven – layer.

| Thin | flute | Single | flute | Double | flute | Triple | flute |

|---|---|---|---|---|---|---|---|

| Name | Thickness | Name | Thickness | Name | Thickness | Name | Thickness |

| A9B | 2mm | K3K | 3±1mm | K=K | 6±1mm | K三K | 9±1mm |

| B9B | 2mm | K3A | 3±1mm | K=A | 6±1mm | A三B | 9±1mm |

| B9C | 2mm | A3A | 3±1mm | K=B | 6±1mm | B三B | 9±1mm |

The number 9 represents the middle corrugated core paper. E flute is called fine flute and can be replaced by the number 9. A flute, B flute and C flute are collectively called coarse flutes and can all be replaced by the number 3. The number 8 represents F flute.

The E flute is represented by 9, which means that there are at least 9 complete corrugation peaks in every 30mm of E flute cardboard. The coarse flute is represented by 3, which means that there are at least 3 complete corrugation peaks in every 30mm of coarse flute cardboard.

- For single flute with a thickness of 3±1MM, the common expressions are: K3K, K3A, A3A.

- For double flute with a thickness of 6±1MM, the common expressions are: K=K, K=A, K=B.

- For triple flute with a thickness of 9±1MM, the common expressions are: K≡K, K#K… and so on.

A, B, C, W, K refer to the quality grades of paper. They are K – grade paper, A – grade paper, B – grade paper, C – grade paper respectively. Among them, K – grade paper is the best, with the order of quality being K > A > B > C.

Expressions of cardboard

For example:

Take a single – corrugated cardboard with A3B paper quality as an example.

- Take B flute as an example, it is read as “A3B, B flute”.

- Take C flute as an example, it is read as “A3B, C flute”.

- Take A flute as an example, it is pronounced as “A3B, A flute”.

Double-wall corrugated board:

- Taking the BC flute paper combination A=B as an example, it is pronounced as “A equals B”. However, it should be noted that in the context of corrugated board, “A=B” actually means A-grade paper + double corrugated + B-grade paper.

- Taking the EC flute paper combination W=A as an example, it is pronounced as “W933A”. Taking the BA flute paper combination A=A as an example, it is pronounced as “A=A, BA flute”.

Triple – wall corrugated board:

- Taking the seven-layer paper with BCB flute, B triple B as an example: B1M1M0M1M1M1B2.

The processes that can be done on the surface of corrugated paper

When there is a facing paper on the corrugated cardboard, various processes can be applied. However, when there is no facing paper, laminating and glazing are not possible, and for local processes, only UV coating can be done.

Except for airplane boxes which don’t need to be glued after being made, products of other box types will be glued by default before leaving the factory.

When kraft paper is used as the corrugated facing paper, it is recommended not to laminate or apply oil.